Our design team at Blender Products is committed to building better environments and communities. We aim to provide clean air, optimize industrial processes, and reduce mankind’s impact on our surroundings. Not only are we dedicated to our technology and applications, but also to providing our customers with valuable solutions.

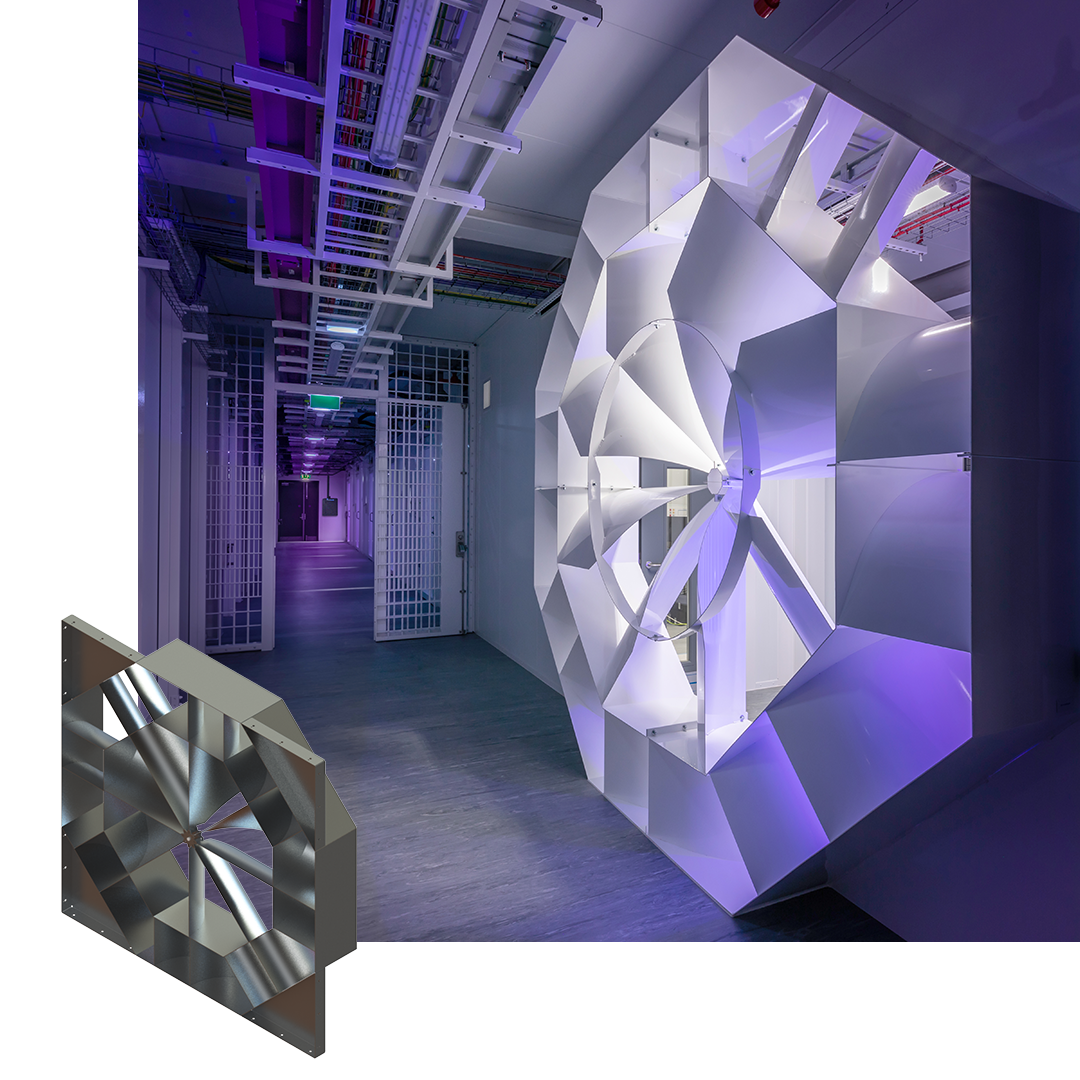

We want to introduce you to our patented Air Blender. It’s the only mixing device on the market that can provide predictable mixing and pressure loss levels at every size and configuration. It works at a lower pressure level and in half the distance than other devices, too. Best of all, an Air Blender can save your business time and money. Here’s how.

It Allows for the Use of Free Cooling

Free cooling is an economical approach to cooling down your building. It uses cold external air to chill water, which can get used in various industrial processes or an air conditioning system. The free cooling process allows you to bypass a mechanical cooling system entirely, thus lowering your cooling expenses.

With an Air Blender installed, you can extend your economizer operations in cold weather conditions. You’ll be able to fully take advantage of free cooling, as well, which will save you a substantial amount of money. This is all because an Air Blender allows for proper mixing. When you apply it to your HVAC system, you can rest assured knowing that it’ll operate at outdoor-air design temperatures.

It Offers Protection Against Freezing

During the winter season, your HVAC equipment components are at risk of freezing. Most notably, you could encounter freeze-stat trips or frozen coils. When this occurs, you have to deal with system downtime and a loss of revenue. Luckily, our design team at Blender Products has the innovative solution you need.

Our Air Blender provides freeze protection. Because it’s efficient at mixing, it prevents air stratification in your air handling unit (AHU). That means frozen coils will be a thing of the past, no matter how cold it gets. You won’t have to waste time waiting for them to thaw or get repaired anymore.

It Ensures Accurate Temperature Sensing

Air stratification in HVAC systems occurs when cool air sinks and warm air rises. If your air isn’t getting properly mixed, it can result in an inefficient system and poor indoor air quality. It’s also what causes coils to freeze.

Velocity and temperature stratification can also render your sensors inaccurate when they happen in your system. That’s a problem because they can lead to poor temperature control within your building. You’ll have to waste time figuring out the cause, too.

As we mentioned, though, our Air Blender prevents air stratification. It properly mixes air, which allows for a more consistent temperature. As a result, your sensors will have a reduced number of errors.

It Reduces Energy Costs

When your system is struggling with air stratification, your energy bill can increase exponentially. You can also encounter poor air circulation and quality inside your building. Those are serious problems! Luckily, you can solve them both by applying our Air Blender.

It’s an efficient product for air mixing and utilizes proper mixing techniques. It reduces air stratification in HVAC systems while improving indoor airflow and maintaining air quality. As a result, you’ll enjoy lower energy costs thanks to a more efficient system. It also welcomes natural ventilation at a stable temperature indoors.

Air stratification is a serious problem within the AHU and HVAC systems for many businesses. It ruins indoor air quality and damages equipment. However, you can eliminate it by applying our patented Air Blender. It ensures accurate sensors, provides freeze protection, utilizes free cooling, and reduces energy costs. It’s the solution your system needs, so discover the benefits of an Air Blender today!

Leave a Comment