At Blender Products in Denver, CO, we develop and provide highly useful technology, products, and systems. Our company strives to build better communities and environments. Every day, we are driven by engineering, and we exist to provide our customers with value.

Our design team at Blender Products are experts and ready to ensure the proper application of our products for our customers. If you’re trying to determine which of our products are right for you, we can help with that as well. Read on to learn a little more about some of them so you can make the right choice for your unique needs.

Channel Blender

Would you like to prevent air stratification while maintaining healthy ventilation rates? The Channel Blender is our most effective product for that. It’s designed to increase the coldest temperature in the plenum to create a more uniform flow pattern and protect coils. It even contains OA and RA control dampers for more effective mixing without an additional footprint.

- Our Channel Blender has several advantages, such as:

- Improved air quality indoors

- Enhanced airflow uniformity

- Reduced operating costs

A Channel Blender is one of two solutions for air stratification HVAC systems. Apply it for benefits such as reduced sensor errors or enhanced ventilation reliability.

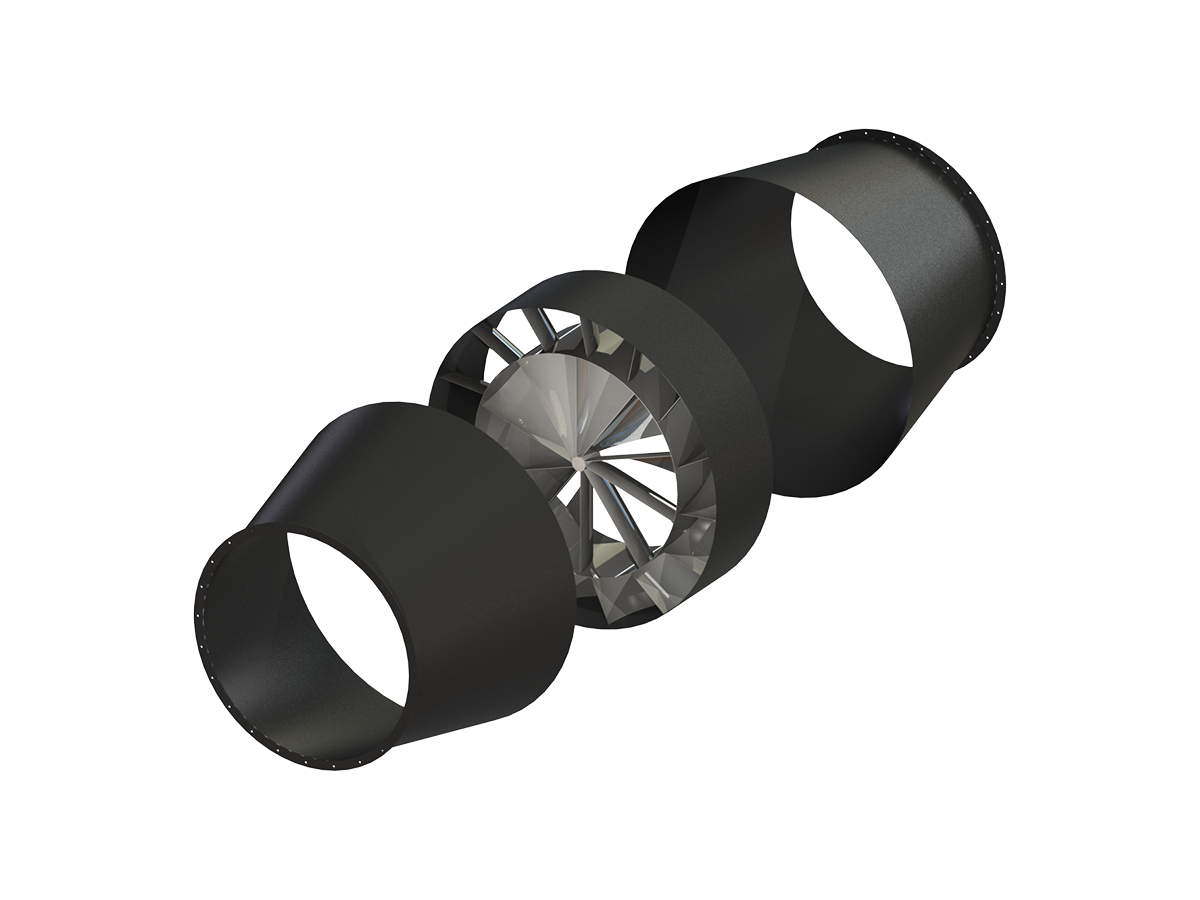

Air Blender

Our patented Air Blender is the only mixing device available that provides predictable mixing and pressure loss levels with each configuration. It supplies higher mixing levels at a lower pressure and half the distance compared to other devices. The Air Blender was designed to mix stratified air streams, which means you get a more even temperature and consistent airflow.

There are a number of things that our Air Blender can help with, like:

- Promoting even coil loading

- Providing freeze protection

- Improving temperature control accuracy

- Extending economizer operation

You can benefit from the Air Blender in other ways, too. It makes indoor air more breathable, and it evens the velocity profile of your systems’ components. It’s also the second solution you could choose to apply to your air stratification HVAC systems.

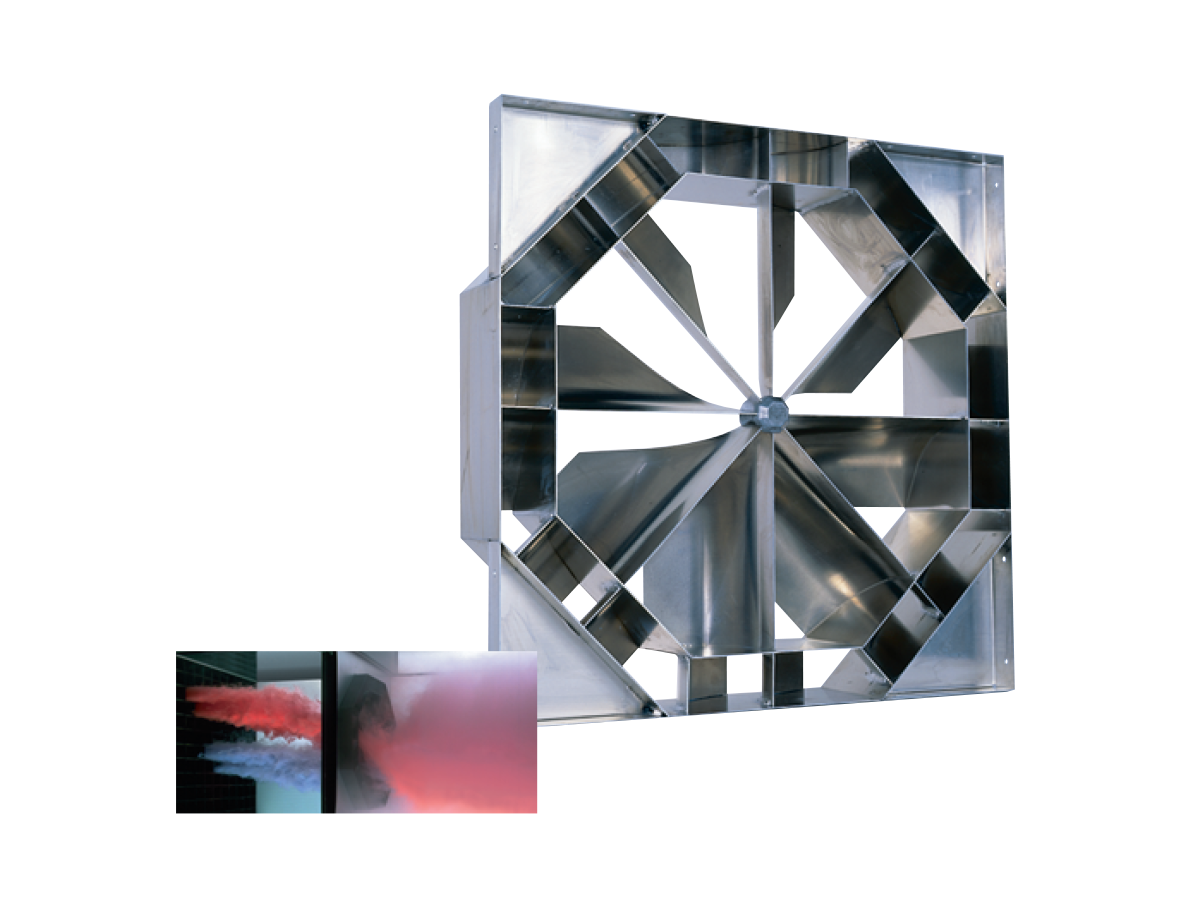

Spark Cooler

Are you facing filter fires and equipment damage to your dust collection systems? It might be a result of metal processing sparks igniting combustibles within the system. This is a serious problem because it could lead to downtime in the production process, which means you’ll be losing revenue.

The solution is a Spark Cooler. It works by creating turbulence that increases the relative velocity, which increases heat transfer and causes sparks to burn out. It has many benefits, including:

- Proven spark mitigation

- No secondary dust accumulation

- Lowest pressure drop compared to other devices

- Reduced filter media damage

Plus, our Spark Cooler is easy to install and leaves zero footprints behind. It eliminates your system maintenance downtime, too.

Gas Blender

Our patented Gas Blender has a variety of uses in different industrial applications. It’s often customized for specific performance needs and used with other system components. When temperature mixing or particle concentration is critical, it’s your best solution because of its capabilities at a low-pressure drop.

The Gas Blender boasts countless benefits, like:

- Predictable mixing for every mixer size

- Reduced velocity maldistribution

- Maximized performance in the shortest distance possible

- Increased sorbent distribution

We recommend our Gas Blender for industrial processes such as velocity or thermal mixing. It also works well for nuclear emissions monitoring, biomass power generation, and coal power generation. It can even get applied to paint rooms or food and powder material handling.

So, which Blender Product is right for you? Ultimately, it depends on your system needs. In most cases, however, we’re able to suggest our patented Air Blender. It’s versatile, beneficial, and capable of reducing air stratification. Discover the benefits of an Air Blender today!