What is an Industrial HVAC Unit and Its Importance in Modern Buildings

In the rapidly evolving landscape of modern architecture and construction, the significance of industrial HVAC units cannot be overstated. These systems play a critical role in maintaining indoor air quality, regulating temperature, and ensuring the overall comfort and productivity of building occupants. According to Dr. Emily Carter, a renowned expert in environmental engineering and HVAC technology, “Industrial HVAC units are the backbone of energy efficiency and sustainability in modern buildings.” This highlights not only their functional importance but also their role in promoting eco-friendly practices within the industry.

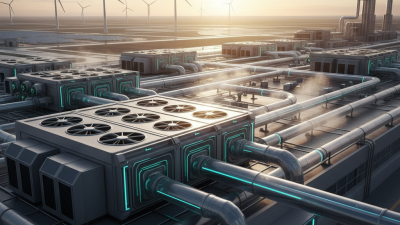

As buildings grow in complexity and scale, the demand for reliable and efficient heating, ventilation, and air conditioning systems has surged. Industrial HVAC units are designed to meet these demands, providing tailored solutions for a variety of environments, from manufacturing plants to commercial spaces. Their ability to handle larger airflows and maintain optimal conditions under varying loads makes them indispensable to the operation of any modern facility. In this context, understanding the intricacies and benefits of these systems is crucial for architects, engineers, and facility managers alike, as they strive to create sustainable and comfortable spaces for work and living.

What is an Industrial HVAC Unit?

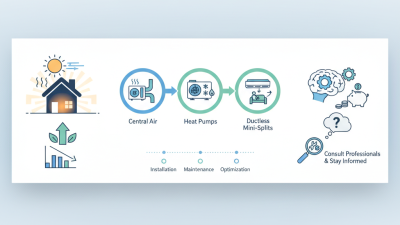

An industrial HVAC unit, or Heating, Ventilation, and Air Conditioning unit, is a system specifically designed to regulate air temperature, humidity, and airflow within large commercial and industrial spaces. Unlike residential HVAC systems, which typically cater to single-family homes, industrial units are built to handle greater capacities and often serve to maintain optimal conditions in manufacturing plants, warehouses, hospitals, and other sizable facilities. These systems can integrate multiple components, including air handlers, chillers, boilers, and exhaust systems, to ensure efficiency and comfort across vast areas.

The importance of industrial HVAC units cannot be understated in modern buildings. They play a crucial role in maintaining a controlled environment, which not only enhances the comfort of employees and visitors but also protects sensitive equipment and materials from extreme temperatures and humidity levels. Furthermore, a well-designed HVAC system can significantly improve air quality, reducing the risks of airborne contaminants and promoting a healthier workspace. With advancements in technology, modern industrial HVAC units are becoming increasingly energy-efficient, leading to reduced operational costs and a lower environmental footprint. This makes them an essential investment for businesses looking to thrive in today’s competitive landscape.

Components of an Industrial HVAC System

An industrial HVAC (Heating, Ventilation, and Air Conditioning) system plays a crucial role in maintaining optimal environmental conditions in large facilities, from manufacturing plants to commercial buildings. At the core of these systems are several essential components that work in tandem to ensure efficiency and efficacy. The most fundamental components include chillers, boilers, air handlers, and ductwork. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the design and maintenance of these components can significantly impact energy consumption, with HVAC systems accounting for approximately 40% of total energy use in commercial buildings.

Chillers and boilers serve as the primary sources of heating and cooling, circulating water or air to regulate temperature throughout the building. Air handlers distribute conditioned air and are often equipped with filters that improve indoor air quality—an aspect that has become increasingly pivotal in modern building design. Ductwork is responsible for transporting the conditioned air to different building areas and involves careful design to minimize air loss and ensure balanced airflow. According to a report from the U.S. Department of Energy, a well-designed industrial HVAC system can reduce energy costs by up to 30%, highlighting the importance of investing in effective components for both efficiency and long-term sustainability.

Moreover, the integration of advanced controls and sensors has revolutionized the functioning of HVAC systems, allowing for real-time monitoring and adjustments based on occupancy and environmental conditions. As industries continue to prioritize energy efficiency and sustainable practices, the role of robust and optimized HVAC system components remains indispensable, contributing not just to operational effectiveness but also to enhancing the overall health and comfort of building occupants.

What is an Industrial HVAC Unit and Its Importance in Modern Buildings - Components of an Industrial HVAC System

| Component | Description | Importance |

|---|---|---|

| Chiller | A cooling system that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. | Essential for maintaining comfortable indoor temperatures and saving energy costs. |

| Boiler | Heats water or fluid to provide steam or hot water for heating purposes. | Vital for heating systems, ensuring consistent thermal comfort, especially in winter months. |

| Air Handling Unit (AHU) | A unit that regulates and circulates air as part of the HVAC system. | Crucial for maintaining air quality and controlling temperature and humidity levels. |

| Ductwork | The system of channels that distribute conditioned air throughout a building. | Important for efficient airflow and temperature control in different areas of a building. |

| Thermostats | Devices that sense temperature and control the HVAC system to maintain desired conditions. | Key in providing comfort and energy efficiency by optimizing temperature settings. |

Benefits of Industrial HVAC in Modern Buildings

Industrial HVAC (Heating, Ventilation, and Air Conditioning) systems play a pivotal role in enhancing comfort and efficiency in modern buildings. One of the primary benefits of these systems is their ability to regulate indoor temperature and air quality effectively. This regulation is essential not only for the comfort of occupants but also for the optimal operation of machinery and equipment that are sensitive to environmental conditions. By maintaining a stable climate, industrial HVAC units can significantly increase productivity and reduce operational downtime.

Additionally, industrial HVAC systems contribute to energy efficiency in large facilities. With advancements in technology, these systems are designed to consume less energy while providing superior performance. This not only translates to lower utility bills but also supports sustainability goals by reducing the carbon footprint of the building. Furthermore, these systems often come equipped with advanced filtration mechanisms, ensuring that the air quality remains high by removing pollutants and allergens. As a result, employees can work in a healthier environment, which can lead to higher morale and reduced absenteeism.

Benefits of Industrial HVAC in Modern Buildings

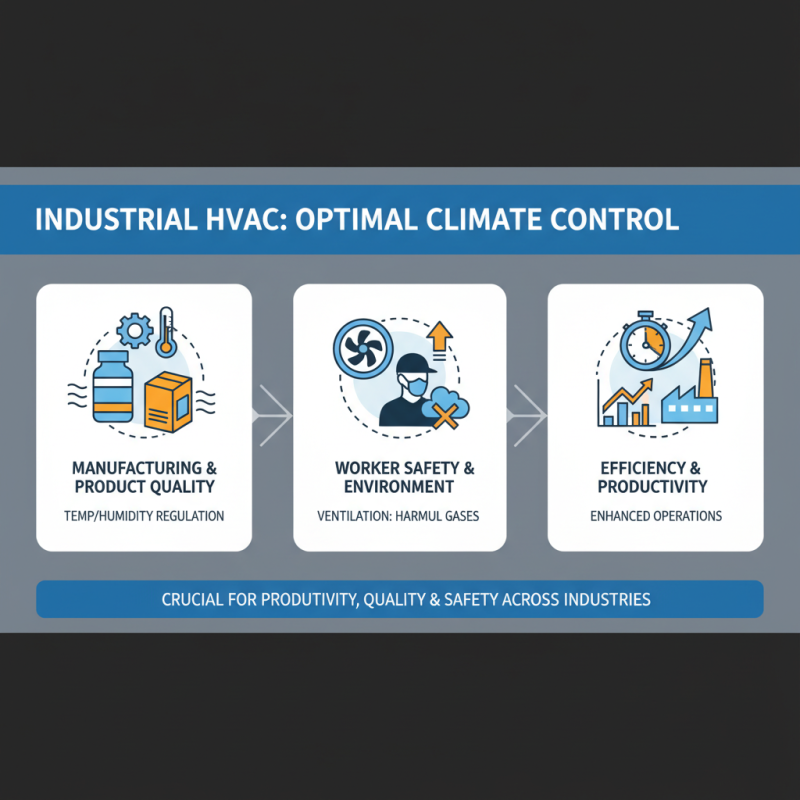

Applications of Industrial HVAC Units in Various Industries

Industrial HVAC (Heating, Ventilation, and Air Conditioning) units play a vital role across various industries by ensuring optimal climate control, which is crucial for efficiency and productivity. In manufacturing settings, these systems regulate temperature and humidity levels, essential for maintaining the quality of products, such as pharmaceuticals or food items. Proper ventilation is also critical in preventing the buildup of harmful gases and ensuring worker safety, thus enhancing the work environment.

In the healthcare sector, industrial HVAC units are integral in maintaining strict air quality standards. They help control pathogens and airborne contaminants, providing a safe and sterile environment for patients and healthcare professionals. Similarly, in data centers, precise temperature control is necessary to prevent overheating and ensure the longevity of sensitive equipment. Additionally, in commercial spaces such as shopping malls or office buildings, these systems contribute to a comfortable atmosphere that enhances customer experience and employee satisfaction. The diverse applications of industrial HVAC units highlight their importance in fostering operational efficiency and ensuring safety across multiple sectors.

Maintenance and Efficiency Considerations for HVAC Systems

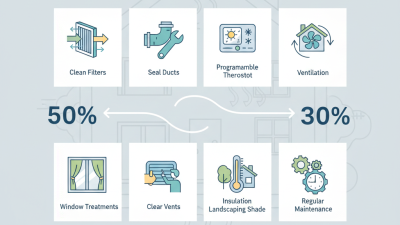

Maintaining an industrial HVAC system is crucial for ensuring optimal efficiency and prolonging the lifespan of the unit. Regular maintenance practices, such as changing air filters, inspecting ductwork for leaks, and checking refrigerant levels can significantly enhance system performance. A well-maintained HVAC system operates more efficiently, leading to lower energy consumption and costs, which is especially important in large buildings where energy expenses can be substantial.

Tips: To keep your industrial HVAC unit running smoothly, schedule bi-annual inspections with qualified technicians. They can identify potential issues early, reducing the likelihood of unexpected breakdowns. Additionally, consider implementing a building management system to monitor and optimize HVAC performance based on real-time data.

Efficiency considerations are essential in the design and operation of HVAC systems. Implementing energy-efficient technologies, such as variable speed drives and advanced controls, can lead to substantial improvements in energy savings. It is also important to educate building occupants about their impact on HVAC efficiency—simple actions like closing doors and windows can prevent energy loss and maintain desired indoor climates.

Tips: Encourage staff training on HVAC best practices. Engaging employees in energy-saving initiatives can foster a collective responsibility for maintaining comfort and efficiency within the building.

Related Posts

-

2025 Top Industrial HVAC Units: Enhance Efficiency with 15% Energy Savings

-

10 Best Industrial HVAC Systems for Optimal Energy Efficiency in 2023

-

What is the Best HVAC System for Home Comfort and Energy Efficiency

-

Top 10 Airflow HVAC Tips for Optimal Home Comfort and Efficiency

-

Why You Should Consider Blender Products for Your Kitchen Needs

-

How to Optimize Airflow in HVAC Systems for Energy Efficiency